Durable and Sustainable Waterborne PU Leather: The Ultimate Guide

By:Admin

In an era where sustainability is becoming the need of the hour, the fashion industry is taking significant steps towards adopting eco-friendly materials and processes. As a part of this movement, {Company Name} has brought forth a revolutionary innovation in the form of waterborne PU leather, catering to the growing demand for ethical and sustainable fashion.

{Company Name} has been a pioneer in the production of high-quality synthetic materials for various industries, including fashion, automotive, and interior design. With a strong focus on innovation and sustainability, the company has embarked on a mission to develop eco-friendly alternatives to traditional leather, which is known for its environmental impact and ethical concerns.

Waterborne PU leather is a cutting-edge material that offers the look and feel of traditional leather, without the use of harmful solvents and chemicals in its production process. Unlike traditional PU leather, which is manufactured using solvent-based coating systems, waterborne PU leather utilizes water-based coating technology, significantly reducing its environmental footprint.

This innovative material not only addresses the environmental concerns associated with traditional leather production but also offers a range of functional benefits. Waterborne PU leather is highly durable, scratch-resistant, and easy to clean, making it a practical choice for a wide range of applications. Moreover, it is available in a variety of textures, finishes, and colors, providing designers and manufacturers with a versatile material to bring their creative visions to life.

In addition to its environmental and functional benefits, waterborne PU leather aligns with the growing consumer demand for ethical and sustainable fashion. Today's consumers are increasingly conscious of the impact of their purchasing decisions and are seeking products that are cruelty-free and environmentally responsible. With waterborne PU leather, {Company Name} is offering a solution that meets these evolving consumer preferences without compromising on style or quality.

Furthermore, {Company Name} is committed to ensuring that the production of waterborne PU leather is in line with the highest standards of ethical and sustainable practices. The company has implemented stringent quality control measures to monitor the entire production process, from raw material sourcing to manufacturing and distribution. By upholding these standards, {Company Name} is setting a new benchmark for sustainability in the synthetic leather industry.

As the fashion industry continues to move towards a more sustainable future, waterborne PU leather is poised to play a pivotal role in reshaping the landscape of materials used in fashion and design. With its eco-friendly composition, durability, and versatility, this innovative material is set to revolutionize the way designers and manufacturers approach their creative endeavors.

{Company Name} is proud to be at the forefront of this sustainable revolution, catering to the needs of the fashion industry while championing the cause of environmental responsibility. Through the development and production of waterborne PU leather, the company is driving positive change and paving the way for a more sustainable and ethical fashion ecosystem.

In conclusion, {Company Name}'s waterborne PU leather stands as a testament to the company's unwavering commitment to innovation and sustainability. By offering a viable alternative to traditional leather, the company is empowering designers, manufacturers, and consumers to make ethical choices without compromising on quality, style, or performance. As the fashion industry continues to evolve, waterborne PU leather is set to lead the way towards a more sustainable and responsible future.

Company News & Blog

Understanding the Meaning of Waterborne: Definition and Examples

When it comes to coatings, there are a multitude of options available on the market. One of the most popular coatings that has gained popularity in recent years is waterborne polyurethane resin coating.Waterborne polyurethane resin coating is a type of coating that offers a high level of durability, flexibility and resistance to abrasion. This type of coating is widely used in a number of industries including construction, automotive, electronics and more. It provides a protective layer that enhances and extends the lifespan of the surface it is applied on.One of the major advantages of waterborne polyurethane resin coating is that it is more environmentally friendly than other alternatives such as solvent-based coatings. Solvent-based coatings emit high amounts of volatile organic compounds (VOCs) which are harmful to both the environment and human health. In contrast, waterborne polyurethane resin coatings have lower levels of VOCs and are therefore more eco-friendly.Waterborne coatings are also easier to apply and require less downtime for curing compared to solvent-based coatings. This leads to higher efficiency in the production process which in turn can increase profitability for businesses.Another advantage of waterborne coatings is that they have improved adhesion to a wide variety of materials such as metal, plastic and even concrete. This makes them versatile and suitable for a wide range of applications.When it comes to waterborne polyurethane resin coatings, one brand that stands out in terms of quality and performance is (brand name). They offer a range of waterborne coatings that provide excellent adhesion, durability and abrasion resistance. Their coatings are also available in a variety of colours and finishes to suit different preferences and applications.In conclusion, waterborne polyurethane resin coatings are an excellent choice for anyone looking for a high-performance coating that is also environmentally friendly. With their excellent adhesion, durability and versatility, they are suitable for a wide range of applications. And with (brand name)’s range of waterborne coatings, you can trust that you are getting a high-quality product that will meet your needs. Don’t hesitate to try out waterborne polyurethane resin coatings today.

Understanding the Significance of CAS 4767-03-7 in China

China 4767-03-7, also known as CAS 4767-03-7, is an important chemical compound that is widely used in various industries. This compound has been in the news recently due to its potential applications in several key sectors. One company that has been making headlines with its use of China 4767-03-7 is {}. {}, a leading chemical company, has been at the forefront of utilizing China 4767-03-7 in innovative ways. The company has a long history of producing high-quality chemicals for a wide range of industries, and their use of China 4767-03-7 is no exception. With their cutting-edge technology and dedication to research and development, {} has successfully integrated this compound into their product lines, offering unique solutions to their customers.One of the key areas where {} has been leveraging China 4767-03-7 is in the production of specialty chemicals. This compound has proven to be essential in the creation of high-performance chemicals that are used in various industrial applications. By incorporating China 4767-03-7 into their manufacturing processes, {} has been able to develop products that offer superior performance and quality, giving them a competitive edge in the market.In addition to specialty chemicals, {} has also been utilizing China 4767-03-7 in the production of advanced materials. This compound has unique properties that make it ideal for use in the creation of innovative materials that are used in construction, automotive, and electronics industries, among others. By harnessing the potential of China 4767-03-7, {} has been able to develop materials that are not only highly durable and versatile but also sustainable, contributing to their commitment to environmental responsibility.Furthermore, {} has been actively exploring the potential of China 4767-03-7 in the field of pharmaceuticals. This compound has shown promise in the development of new drugs and medical treatments, and {} has been at the forefront of research in this area. By investing in cutting-edge research and collaborating with leading experts in the field, the company aims to create breakthrough pharmaceuticals that can improve the quality of life for people around the world.In addition to their innovative use of China 4767-03-7, {} is also committed to ensuring the safety and sustainability of their products. The company adheres to strict quality control standards and has implemented environmentally friendly practices in their manufacturing processes. By prioritizing safety and sustainability, {} aims to be a responsible corporate citizen and contribute to a greener, more sustainable future.As {} continues to explore the potential of China 4767-03-7 in various applications, the company remains dedicated to pushing the boundaries of what is possible in the chemical industry. Through their relentless commitment to innovation and excellence, {} is poised to make a lasting impact in the market and create value for their customers and partners.In conclusion, China 4767-03-7, also known as CAS 4767-03-7, is a versatile chemical compound that holds great potential in a wide range of industries. With their innovative use of this compound, combined with their dedication to quality and sustainability, {} is setting new standards in the chemical industry and shaping the future of manufacturing and technology.

Benefits of Waterborne Polyurethane for Your Next Project

Waterborne Polyurethane, a new innovation in the world of coatings, is making waves in the industry. This environmentally friendly and highly durable product is set to revolutionize the way coatings are applied in a wide range of applications.[Company Name], a leading producer of industrial coatings, is at the forefront of this exciting development. With a strong commitment to sustainability and innovation, the company has been investing heavily in research and development to bring Waterborne Polyurethane to the market.The key advantage of Waterborne Polyurethane is its low environmental impact. Traditional solvent-based coatings release harmful volatile organic compounds (VOCs) into the atmosphere, contributing to air pollution and posing health risks to workers and the general public. In contrast, Waterborne Polyurethane is water-based and contains minimal VOCs, making it a much more sustainable and eco-friendly option.In addition to its environmental benefits, Waterborne Polyurethane also offers outstanding durability and performance. It provides excellent resistance to chemicals, abrasion, and impacts, making it ideal for a wide range of applications, including industrial equipment, automotive components, and architectural finishes. Its high level of adhesion and flexibility ensures a long-lasting and high-quality finish, even in the harshest of conditions.Furthermore, the application of Waterborne Polyurethane is highly efficient, thanks to its fast-drying properties and ease of use. This not only saves time and labor costs for manufacturers and applicators but also contributes to a reduction in energy consumption and overall production waste.[Company Name] has been working closely with customers to develop tailored solutions using Waterborne Polyurethane, meeting their specific performance and sustainability requirements. The company's team of technical experts has been providing valuable support and guidance throughout the adoption process, ensuring successful and seamless integration of this innovative coating technology.As a result of its extensive R&D efforts, [Company Name] has also developed a comprehensive range of complementary products and services to support the use of Waterborne Polyurethane. This includes primers, topcoats, and additives, as well as technical training and on-site support to optimize application processes and ensure the best possible outcomes.The introduction of Waterborne Polyurethane aligns with [Company Name]'s broader sustainability strategy, which focuses on reducing environmental impacts across its entire product portfolio. By offering customers a more sustainable alternative to traditional solvent-based coatings, the company is contributing to the global effort to minimize the environmental footprint of industrial processes and products.In addition, the adoption of Waterborne Polyurethane presents significant business opportunities for [Company Name]'s customers, as they can enhance their own sustainability credentials and meet the increasing demand for eco-friendly and high-performance coatings. This, in turn, allows them to differentiate themselves in the market and build stronger relationships with environmentally conscious consumers and stakeholders.Looking ahead, [Company Name] is committed to further advancing the development and application of Waterborne Polyurethane, as well as exploring new opportunities for sustainable innovation in the coatings industry. By leveraging its expertise and resources, the company aims to continue driving positive change and delivering value to its customers, while simultaneously contributing to a more sustainable and environmentally responsible future.In conclusion, Waterborne Polyurethane represents a significant breakthrough in the world of coatings, offering a compelling combination of environmental sustainability, exceptional performance, and operational efficiency. With [Company Name] leading the charge in its development and application, this innovative technology is poised to transform the industry and create new opportunities for businesses to thrive in a sustainable and responsible manner.

New Water-Based Dispersions Offer High-Quality PU System Solutions

: Advantages, Uses, and Future Trends.Water-based polyurethane dispersion or WBPU is a sustainable alternative to traditional solvent-based polyurethane (PU) systems. These dispersions are dispersed polyurethane particles, stabilized in water, and can be used as film-forming agents in various applications. The aqueous nature of these dispersions makes them environmentally friendly, easy to handle, and enable low VOC emissions. These dispersions have quickly become popular in various industries due to their unique advantages.Advantages of Water Based Polyurethane Dispersion:1. Eco-friendlyWBPU is water-based and contains no harmful chemicals, heavy metals, or solvents, making them eco-friendly. They do not require the use of toxic chemicals and are not flammable, making them safer to use. The absence of solvents significantly reduces the negative impact on the environment and on human health, making them an ideal choice for manufacturers to meet sustainability goals.2. Excellent PropertiesWBPU provides excellent mechanical properties, abrasion resistance and exhibits good chemical resistance to most chemicals, oils, and greases. They have a stable color fastness, which results in longer-lasting products. They are resistant to UV and thermal degradation and do not damage the substrate surfaces, resulting in high-quality, durable products.3. Easy to ApplyWBPU dispersions are easy to apply using conventional techniques such as spray, brush, roll, and dip coating. They can also be used on different substrates, including wood, metal, plastic, and textiles. They dry quickly, enabling a faster production process and lower production costs.4. Wide Application RangeWBPU dispersions have a wide range of applications in various industries such as automotive, construction, furniture, textiles, paper, and packaging. They can be used for coatings, adhesives, sealants, and composites. In the textile industry, they are used for apparel, footwear, and leather goods.Uses of Water Based Polyurethane Dispersion:1. AutomotiveWBPU is an ideal material for automotive coatings due to its excellent chemical resistance, corrosion protection, and durability. It is used for coatings on bumpers, mirrors, and other exterior car parts.2. ConstructionWBPU is commonly used for coatings in the construction industry due to its high durability and excellent performance. It is used for flooring, concrete coatings, and waterproofing.3. FurnitureWBPU is an excellent choice for furniture coatings, including chairs, tables, and cabinets. The coatings provide excellent hardness and scratch resistance, resulting in long-lasting furniture.4. TextilesWBPU is used in the textile industry for apparel, footwear, and leather goods. It provides excellent water resistance, softness, and durability, resulting in high-quality products.Future Trends:The demand for water-based polyurethane dispersions is growing worldwide due to their eco-friendly and sustainable nature. The awareness of sustainability and a movement towards green manufacturing is driving the growth of this market. Several governments have implemented regulations on the use of traditional solvent-based coatings, which has led to an increased demand for water-based coatings.In conclusion, water-based polyurethane dispersions provide excellent properties, environmental benefits, and a wide range of applications. They are ideal for various industries such as automotive, construction, furniture, and textiles. As the world moves towards sustainability, WBPU will continue to grow in demand, resulting in a more sustainable and eco-friendly future.

High-Quality Resin Based Coating for Excellent Protection and Durability

Resin Based Coating Continues to Transform the Coating IndustryResin Based Coating, a leading provider of advanced resin-based coating solutions, is revolutionizing the coating industry with its innovative products and cutting-edge technology. The company, which has been at the forefront of resin-based coating development for over a decade, continues to set new standards for performance, durability, and sustainability in the industry.The company's wide range of resin-based coating products caters to various industrial sectors, including automotive, aerospace, marine, construction, and more. Its advanced technology and commitment to quality have earned it a reputation as a trusted provider of high-performance coating solutions that meet the most demanding requirements. Founded in the early 2000s, Resin Based Coating has grown from a small startup to a global leader in resin-based coating technology. The company's success can be attributed to its relentless focus on research and development, as well as its commitment to delivering exceptional value to its customers.One of the key strengths of Resin Based Coating is its in-house research and development team, which is constantly working on developing new and improved resin-based coating solutions. These cutting-edge products are designed to address the evolving needs of the industry and provide customers with superior performance, durability, and sustainability.The company's dedication to innovation has resulted in a range of advanced resin-based coating products that offer unmatched performance and longevity. These products are designed to withstand the harshest environmental conditions and provide long-lasting protection for a wide range of surfaces.One of the company's flagship products is its high-performance resin-based automotive coatings, which are widely used in the automotive industry for their exceptional durability, weather resistance, and aesthetic appeal. These coatings are designed to protect vehicle exteriors and interiors from the damaging effects of UV radiation, extreme temperatures, and harsh chemicals, ensuring that vehicles maintain their appearance and value for years to come.In addition to automotive coatings, Resin Based Coating offers a variety of other products, including marine coatings, aerospace coatings, industrial coatings, and more. All of these products are formulated to deliver superior protection and performance, making them a top choice for companies seeking the best coating solutions for their specific needs.Furthermore, the company is committed to sustainability and environmental responsibility. It has developed a range of eco-friendly resin-based coating products that are free from harmful chemicals and toxins, ensuring that they have minimal impact on the environment. These sustainable products are designed to help companies reduce their carbon footprint and contribute to a cleaner, healthier planet.Resin Based Coating is also known for its exceptional customer service and support. The company's team of coating experts works closely with customers to understand their unique requirements and provide tailored solutions that meet their needs. Whether it's product selection, application support, or technical assistance, the company's dedicated staff is always ready to help customers achieve the best results.Looking ahead, Resin Based Coating is poised to continue leading the way in resin-based coating technology. With its strong focus on research and development, commitment to quality and sustainability, and dedication to customer satisfaction, the company is well-positioned to drive further innovation and advancement in the coating industry.In conclusion, Resin Based Coating has established itself as a global leader in resin-based coating technology, delivering high-performance, durable, and sustainable solutions to a wide range of industrial sectors. With its focus on innovation, quality, and customer satisfaction, the company is set to continue transforming the coating industry and providing customers with the best coating solutions available.

High-quality Dimethylolbutanoic and Dimethylolpropionic Acids available at Jiangxi JiYu New Material Co. Ltd.

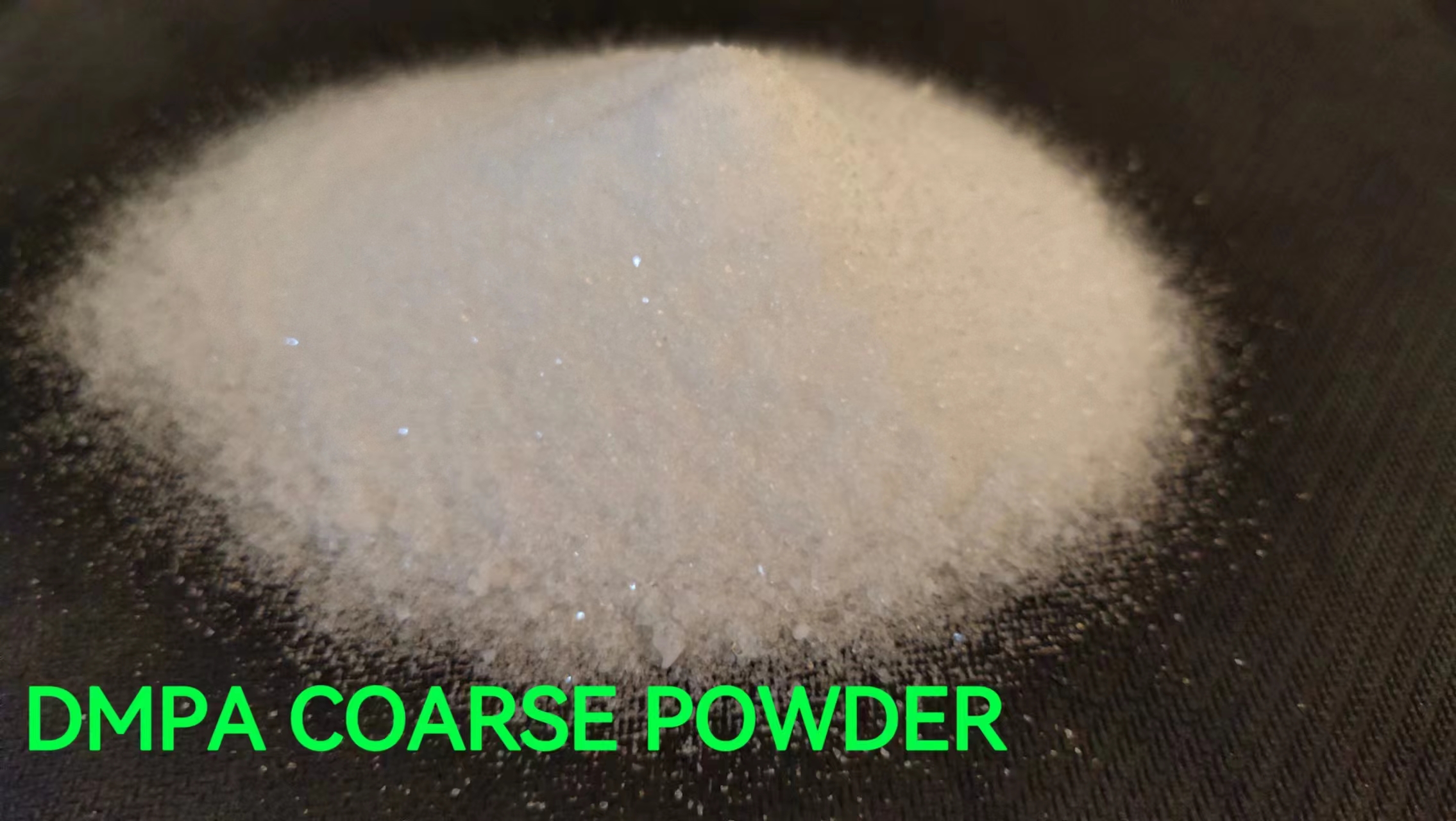

Jiangxi JiYu New Material Co., Ltd. is a modern high-tech enterprise that specializes in the research, development, production, and sale of Dimethylolbutanoic Acid, Dimethylolpropionic Acid, DMBA, DMPA, and other chemical products. Founded in August 2016, the company is located in Lichuan Industrial Park, Fuzhou of Jiangxi Province and covers a total area of 33192 square meters. Jiangxi JiYu New Material Co., Ltd. has been at the forefront of innovation and development in the chemical industry. With a registered capital of RMB 20 million Yuan, the company has invested heavily in research and development to create new and improved products tailored to meet the ever-changing demands of the markets. Dimethylolbutanoic Acid and Dimethylolpropionic Acid are two of the major products produced by Jiangxi JiYu New Material Co., Ltd. DMBA is a colorless, odorless, and highly reactive organic compound that is characterized by its high acidity and excellent cross-linking properties. DMPA, on the other hand, is a white crystalline powder that is widely used in the production of coatings, adhesives, and synthetic resins. The manufacturing process for Dimethylolbutanoic Acid and Dimethylolpropionic Acid involves a complex series of chemical reactions that are carefully controlled and monitored to ensure the highest levels of purity and quality. The raw materials used in the production of these chemicals are of the highest quality and are rigorously tested to ensure they meet the strictest standards. The products produced by Jiangxi JiYu New Material Co., Ltd. have a wide range of applications in various industries. For example, DMBA is used in the production of resins, coatings, and paints, while DMPA is commonly used as a building block in the production of polyester resins, urethane resins, and alkyd resins. In addition to its high-quality products, Jiangxi JiYu New Material Co., Ltd. is also known for its outstanding research and development capabilities. The company has a team of highly experienced and knowledgeable researchers who are dedicated to developing new and improved products for the market. These researchers have access to state-of-the-art equipment and facilities, allowing them to conduct cutting-edge research in the field of chemical science. Jiangxi JiYu New Material Co., Ltd. is committed to providing its customers with the highest quality products and services. The company has implemented a comprehensive quality control system that covers every aspect of its production process. From raw materials selection to final product inspection and packaging, every step in the production process is carefully monitored to ensure that the products meet or exceed the highest industry standards. The company is also committed to sustainable and eco-friendly production practices. It has implemented a number of measures to reduce its environmental impact, including the use of renewable energy sources, the recycling of waste materials, and the adoption of energy-efficient production processes. Overall, Jiangxi JiYu New Material Co., Ltd. is a leading player in the chemical industry, known for its innovative products, outstanding research and development capabilities, and commitment to quality and sustainability. The company's products, including Dimethylolbutanoic Acid, Dimethylolpropionic Acid, DMBA, and DMPA, have a wide range of applications in various industries, and are trusted by customers around the globe.

The Benefits of Using a 2-Component Polyurethane Adhesive

article about the benefits of using 2 Part Polyurethane Adhesive in the manufacturing industry.[Insert headline]: The Evolution of 2 Part Polyurethane Adhesive: Revolutionizing the Manufacturing IndustryThe manufacturing industry is always in pursuit of solutions that can provide long-term durability and strength for a variety of applications. Advances in technology and materials over the years have led to the development of many cutting-edge adhesives. Out of all the different types of adhesives, 2 Part Polyurethane Adhesive (PU) has proved to be one of the best and most versatile options available today.2 Part Polyurethane Adhesive is a cross-linking adhesive that utilizes two different components that are mixed together just before application. This adhesive type is versatile and can be used in a wide range of applications including automotive, aerospace, construction, and electrical among many others. The adhesive is applied by mixing the two parts together, which initiates a chemical reaction that causes the adhesive to cure.The benefits of using 2 Part Polyurethane Adhesive are numerous, and this adhesive is widely considered to be one of the best when it comes to strength, durability, and its ability to bond with different materials. One of the key benefits of using 2 Part Polyurethane Adhesive is its ability to bond a wide range of materials, including metals, plastics, composites, and even dissimilar substrates. This ability means that it's an ideal choice for manufacturers that are looking for a product that can bond different materials as it saves time and production costs.2 Part Polyurethane Adhesive is also highly resistant to moisture and chemicals. This makes it an excellent choice for applications where the adhesive will come into contact with water, solvent, or other chemicals. The adhesive has excellent resistance to UV light and does not deteriorate over time, making it a reliable application in outdoor environments.Another significant benefit of 2 Part Polyurethane Adhesive is its high resistance to temperature extremes. Its bonding strength remains reliable even in high-temperature applications and can withstand exposure to extreme cold temperatures.In addition to these excellent benefits, 2 Part Polyurethane Adhesive is known for its ease of application. It has a relatively quick drying time, and it does not require any special equipment to apply. The adhesive can be easily applied using a brush, roller, or sprayer, making it an ideal choice for both small and large-scale projects.Moreover, this adhesive is an eco-friendly option, as it does not generate volatile organic compounds (VOCs), which helps manufacturers meet and exceed the environmental regulations.Companies worldwide have adopted 2 Part Polyurethane Adhesive for its superior bonding capabilities and the potential it offers to speed up production. But, above all, it has contributed to product quality and customer satisfaction. For example, in the automotive industry, 2 Part Polyurethane Adhesive has revolutionized the manufacturing process. Its high strength, durability, and excellent chemical resistance make it an ideal choice for automotive applications such as bonding of car chassis and body panels.Several industries, such as wind energy, aerospace, and construction, have also adopted this adhesive for its versatile capabilities. In wind energy, 2 Part Polyurethane Adhesive is used in bonding rotor blades, which contributes to the development of clean energy and sustainable future technology.In the aerospace industry, the development of lightweight airplanes demands an adhesive that delivers exceptional strength, flexibility, and weather resistance. 2 Part Polyurethane Adhesive has proven to be one of the most reliable bonding agents in this field. It is used to bond composite materials with other substrates, making the structures strong and safe for use.The construction industry also uses 2 Part Polyurethane adhesive extensively. It is used in bonding flooring, insulation materials, metal, concrete, and masonry constructions. Its ability to bond different substrates makes it quite efficient in sealing leakages, filling gaps, or cracks, and in securing heavy load-bearing components.A leading manufacturer of this adhesive has produced a range of products that cater to different industries' needs. Their products have been trusted for providing excellent bonding capabilities and have been used in a wide range of applications. Their technical team of experts can work with customers to develop tailormade products suitable for specific industries and applications.In conclusion, the use of 2 Part Polyurethane Adhesive has revolutionized the manufacturing industry. Its superior bonding capabilities, versatility, chemical and weather resistance, and ease of application make it a reliable choice for various industries worldwide. With its continued development and application in new areas, it's no wonder that this adhesive has become a staple in many manufacturing industries.

Thermoplastic Polymer Used for Padding and Insulation in Furniture and Clothing

Polyurethane Demand Soars as Consumers Embrace Eco-Friendly AlternativesAs consumers become increasingly concerned about preserving the environment and combating climate change, the demand for eco-friendly products has skyrocketed across different industries. One notable beneficiary of this trend is the polyurethane industry. With its versatile applications in the fabrication of comfort-oriented furniture, clothing, and packaging materials, polyurethane has become popular in recent years as a sustainable alternative to other materials.Polyurethane is a thermoplastic polymer that contains the group NHCOO; it is widely used for insulation and padding in furniture, clothing, and packaging materials. It has also become a common ingredient in the manufacture of resins used in adhesives, elastomers, and fillers. Due to its low toxicity, insulating properties, and ability to reduce carbon emissions, polyurethane is emerging as the preferred material of choice for consumers across different applications.As the demand for polyurethane continues to climb, (company) has stepped up its investment in research and development to improve the quality and sustainability of its products. The company has adopted a multi-pronged approach to ensure that its manufacturing processes are environmentally friendly and adhere to the highest standards of safety and quality.One of the key technologies that (company) has invested in is the water-blown polyurethane foam system. This system replaces the traditional blowing agent, which uses chlorofluorocarbons (CFCs) that are harmful to the environment. The water-blown polyurethane foam system uses a safe and sustainable blowing agent, which results in less carbon emissions and a lower carbon footprint compared to its predecessor.Another technology that (company) has invested in is the EcoFlex system. This system uses a blend of vegetable oils and petroleum to manufacture eco-friendly polyurethane that has a reduced carbon footprint. The EcoFlex system is not only environmentally friendly but also produces superior quality products that offer a unique combination of comfort, durability, and performance.In addition to these technologies, (company) has also established a robust recycling program aimed at reducing waste and promoting sustainable manufacturing. The program enables the company to recover and reuse end-of-life polyurethane products, which are converted into new products, further reducing the carbon footprint of the manufacturing process.With increased global awareness of the need to adopt sustainable practices, the demand for environmentally friendly products, including polyurethane, is expected to continue to surge. (Company name) intends to continue investing in sustainable technologies and research to meet the growing demand for eco-friendly products while maintaining its commitment to safety and quality.In conclusion, the polyurethane industry has become a key player in the shift towards sustainable manufacturing. Rather than relying on traditional manufacturing processes that contribute to environmental degradation, companies like (company name) are investing in sustainable technologies that promote the use of eco-friendly products. The increased adoption of these systems not only benefits the environment but also ensures that consumers receive high-quality, durable, and comfortable products that adhere to the highest standards of safety and quality.

Top Benefits of Water-Based Polyurethane Finish for Your Wood Projects

Title: Water-Based Polyurethane Finish: An Innovative Solution for Environmentally Friendly CoatingIntroduction:In recent years, the growing concern for sustainability and environmental protection has led to the development of various eco-friendly products. In line with these sustainable practices, {Company Name}, a leading manufacturer in the coating industry, has introduced a groundbreaking water-based polyurethane finish that offers a superior alternative to traditional solvent-based coatings. This innovative solution not only ensures excellent durability and aesthetics but also minimizes its impact on the environment.Unveiling the Water-Based Polyurethane Finish:Water-based polyurethane finish is a technologically advanced coating designed to meet the needs of environmentally conscious consumers without compromising on performance. Unlike traditional solvent-based finishes, this innovative product utilizes water as its primary solvent, reducing harmful emissions and limiting the use of toxic chemicals.Benefits of the Water-Based Polyurethane Finish:1. Environmental Friendliness:With its water-based formulation, this polyurethane finish significantly reduces volatile organic compounds (VOCs) emissions, which are known to contribute to air pollution and health concerns. The reduced VOC content makes it a wise choice for both residential and commercial applications.2. Enhanced Durability:Despite being eco-friendly, this water-based polyurethane finish doesn't compromise on durability. It exhibits exceptional resistance to scratches, stains, and general wear and tear. Its robust protective layer ensures that surfaces remain intact and aesthetically pleasing for years to come.3. Quick Drying Time:Thanks to its water-based composition, this finish offers a shorter drying time compared to solvent-based options. Consequently, it allows for faster production cycles during both manufacturing and application processes. This advantage not only increases productivity but also reduces energy consumption, contributing to a more sustainable production environment.4. Versatility:The water-based polyurethane finish is suitable for various surfaces, including wood, ceramics, metals, and plastics. Its versatile nature allows it to be used in a wide range of industries, such as furniture manufacturing, automotive, construction, and more. This diverse application potential makes it a go-to solution for many businesses looking to balance performance with environmental responsibility.Company Name's Commitment to Sustainability:{Company Name} has always been at the forefront of promoting sustainability within the coating industry. With the introduction of the water-based polyurethane finish, the company solidifies its commitment to developing eco-friendly solutions that meet customer expectations while minimizing the impact on the environment.Through extensive research and development, the company has formulated a unique blend of water-based resins, crosslinkers, additives, and pigments to create a finish that is both environmentally friendly and high performing. Additionally, their production facilities have incorporated energy-efficient practices, reducing waste and ensuring responsible resource consumption.In collaboration with customers and industry partners, {Company Name} continuously strives to find better ways to reduce the environmental footprint associated with coatings. By emphasizing sustainable practices and innovative products like the water-based polyurethane finish, they aim to inspire other companies in the industry to follow suit and contribute towards a greener future.Conclusion:The introduction of {Company Name}'s water-based polyurethane finish is a significant step towards more sustainable coating solutions. By offering enhanced durability, quick drying times, and versatility across various industries, this environmentally friendly finish proves that a commitment to the environment does not have to come at the cost of performance.As businesses and households increasingly prioritize sustainability, the demand for socially responsible products continues to grow. With its water-based formulation, this polyurethane finish is well-positioned to meet these demands and make a positive impact on both the coating industry and the planet.

Benefits of Polyurethane Coating on Leather: A Durable and Resilient Option

Title: Revolutionary Polyurethane Treatment Enhances Leather Quality and SustainabilityIntroduction:Leading the way in innovation and sustainability, a reputable name in the leather industry has introduced a groundbreaking polyurethane treatment that revolutionizes the quality and durability of leather products. This pioneering technology not only enriches the leather's aesthetic appeal but also enhances its performance while significantly reducing environmental impact. Embracing the vision of sustainability, the company has committed itself to adopt mindful practices while continuing to raise the bar in leather manufacturing.1. An Unparalleled Breakthrough in Leather Enhancement:Revolutionizing the leather industry, the development of a cutting-edge polyurethane treatment by a renowned leather manufacturer has raised the bar for quality and durability. By utilizing state-of-the-art technology, the company has successfully formulated a proprietary blend that seamlessly bonds to leather, providing enhanced aesthetics, exceptional durability, and improved performance.2. Elevated Aesthetics:Gone are the days of acquirinng leather products plagued by inconsistencies and imperfections. The innovative polyurethane treatment ensures a smooth, refined finish while expertly maintaining the leather's natural grain and suppleness. This transformative process allows for an array of rich and vibrant colors that don't fade over time, providing an unmatched level of visual appeal and longevity.3. Unparalleled Durability and Longevity:With the introduction of this revolutionary treatment, the durability of leather products has reached new heights. The newly fortified leather surface resists scratches, abrasions, and moisture, offering peace of mind to consumers who seek long-lasting products. By integrating polyurethane into the leather matrix, this pioneering process adds an extra layer of reinforcement without compromising the leather's tactile qualities.4. A Sustainable Solution:Amid growing concerns about the environmental impact of leather manufacturing, this polyurethane treatment embodies the commitment of the company to prioritize sustainability. By employing this breakthrough technology, the company significantly reduces water consumption and eliminates the use of harmful chemicals typically required in traditional leather tanning processes. This approach aligns with the company's dedication to responsible manufacturing, prioritizing both product performance and environmental preservation.5. Versatility and Adaptability:The revolutionary polyurethane treatment offers unparalleled versatility, enabling leather to excel in a myriad of applications. From high-fashion garments to automotive upholstery, this technology caters to various industries demanding exceptional quality and durability. Furthermore, this innovation ensures that the treated leather retains its original hand-feel, making it a preferred choice for leather product enthusiasts worldwide.6. Consumer Confidence and Industry Recognition:With a strong commitment to quality and innovation, the company has garnered significant recognition within the industry and has gained the confidence of consumers across the globe. By continuously pushing the boundaries of leather manufacturing, this renowned brand has positioned itself as a pioneer, offering a superior alternative to conventional leather treatments. The positive reception from industry experts and customers further validates the efficacy and desirability of this polyurethane treatment.Conclusion:The integration of polyurethane treatment into leather production marks a turning point in the industry, effectively elevating the quality and sustainability of leather products. With its unrivaled combination of enhanced aesthetics, exceptional durability, and revolutionary environmental consciousness, this groundbreaking technology has solidified the position of the company as an industry leader. As the world becomes increasingly conscious of environmental impact, this innovative solution sets the benchmark for responsible leather manufacturing, inspiring other companies to follow suit.