Durable Water Borne Polyurethane: What You Need to Know

By:Admin

With the increasing focus on sustainable and environmentally friendly solutions, the global water borne polyurethane market has witnessed significant growth in recent years. Water borne polyurethane, also known as WBPU, is a versatile coating material that offers a wide range of benefits such as high performance, durability, and low VOC emissions. This has led to a surge in demand for water borne polyurethane in various industries including automotive, construction, and furniture, among others.

One of the leading companies in the water borne polyurethane market is {}, a global leader in sustainable coating solutions. The company has a strong presence in the global market and offers a wide range of water borne polyurethane products that cater to the diverse needs of its customers. With a focus on innovation and sustainability, {} has been at the forefront of developing cutting-edge water borne polyurethane solutions that meet the highest standards of performance and environmental responsibility.

The increasing demand for water borne polyurethane can be attributed to a number of factors. First and foremost, the growing awareness about the harmful effects of traditional solvent-based coatings has led to a shift towards more sustainable alternatives. Water borne polyurethane offers a viable solution as it significantly reduces the emission of volatile organic compounds (VOCs), which are known to have detrimental effects on human health and the environment. This has prompted regulatory authorities to impose stringent regulations on VOC emissions, further driving the demand for water borne polyurethane.

Additionally, the automotive industry has emerged as a key consumer of water borne polyurethane, particularly for coatings used in the production of vehicles. The automotive sector has been increasingly adopting water borne polyurethane due to its superior performance, excellent adhesion, and resistance to corrosion. Moreover, the construction industry has also shown a growing preference for water borne polyurethane, especially for applications such as flooring, wood coatings, and architectural coatings. The use of water borne polyurethane in these industries not only enhances the durability of the products but also contributes to a healthier and safer environment for workers and end-users.

{} has been at the forefront of meeting the growing demand for water borne polyurethane by continuously innovating and expanding its product portfolio. The company's commitment to sustainability is evident in its efforts to develop water borne polyurethane formulations that are not only high-performing but also eco-friendly. By investing in research and development, {} has been able to introduce advanced water borne polyurethane products that offer superior protection and longevity while minimizing the environmental impact.

Furthermore, {} has been actively collaborating with its customers to develop customized water borne polyurethane solutions that address their specific needs and requirements. This customer-centric approach has enabled the company to build strong partnerships and foster long-term relationships with clients across different industries. {}'s technical expertise and dedicated support have been instrumental in helping customers achieve their sustainability goals while maintaining the highest standards of quality and performance.

Looking ahead, the water borne polyurethane market is poised for continued growth as industries increasingly prioritize sustainability and environmental responsibility. As the demand for eco-friendly coating solutions continues to rise, {} remains committed to leading the way in providing innovative, high-quality water borne polyurethane products. By leveraging its expertise and resources, the company is well-positioned to capitalize on the opportunities presented by the growing market for water borne polyurethane and drive the advancement of sustainable coatings in the years to come.

Company News & Blog

What Does Waterborne Mean in Terms of Transportation?

Coatings: Benefits and ApplicationsWaterborne epoxy coatings are a type of protective coating used to prevent corrosion and damage to surfaces exposed to moisture and other environmental factors. These coatings use water as the primary solvent for the resin, making them an eco-friendly alternative to solvent-based coatings. In this blog post, we will explore the benefits and applications of waterborne epoxy coatings and how they can help protect various surfaces, including floors, walls, and industrial equipment.Benefits of Waterborne Epoxy CoatingsWaterborne epoxy coatings offer numerous benefits compared to traditional solvent-based coatings. Here are some of the key advantages of waterborne coatings that make them an ideal choice for a wide range of applications.1. Eco-Friendly: Waterborne coatings are free of harmful VOCs (volatile organic compounds) that can harm the environment and pose a risk to human health. They meet strict environmental standards and can be used in areas where solvent-based coatings are prohibited.2. Durability: Waterborne epoxy coatings have excellent bonding strength and can provide long-lasting protection against corrosion, abrasion, and chemical damage.3. Fast Drying: Waterborne coatings dry faster than traditional solvent-based coatings, which can significantly reduce the downtime required for coating and maintenance projects.4. Versatility: Waterborne coatings are suitable for different surfaces such as concrete, metal, and wood. They can be applied to floors, walls, and equipment in various industries, including manufacturing, healthcare, hospitality, and food processing.Applications of Waterborne Epoxy CoatingsWaterborne epoxy coatings are commonly used in various applications, including:1. Flooring: Waterborne epoxy coatings can be used as a topcoat for concrete floors to provide a seamless, durable finish that is resistant to abrasion, chemicals, and stains. They can be tinted to match any color, making them a popular choice for decorative applications.2. Walls: Waterborne epoxy coatings can be used on walls in facilities that require frequent cleaning, such as hospitals, laboratories, and food processing plants. These coatings provide excellent chemical and water resistance, making them ideal for areas subjected to harsh cleaning agents.3. Equipment: Waterborne epoxy coatings can be applied to industrial equipment to protect against corrosion and increase its lifespan. These coatings can withstand high temperatures and harsh chemicals, making them ideal for equipment used in heavy industries.In conclusion, waterborne epoxy coatings are an eco-friendly and durable alternative to traditional solvent-based coatings. Their versatility and fast-drying properties make them an ideal choice for a wide range of applications, including flooring, walls, and equipment. If you need protective coating on surfaces that are exposed to moisture, chemicals, or other environmental factors, waterborne epoxy coatings might be the ideal solution to ensure long-lasting protection.

Waterborne Acrylic Resin: Benefits, Uses, and Applications

of elite coating company, aims to provide high-quality, environmentally-friendly coatings for various industrial and commercial applications. The company recently introduced a new product, Waterborne Acrylic Resin, which is expected to revolutionize the industry with its superior performance and eco-friendly features.Waterborne Acrylic Resin is a type of coating that is made from acrylic polymers dispersed in water. It is known for its excellent durability, adhesion, and weather resistance, making it ideal for use in a wide range of applications such as automotive, architectural, and industrial coatings. Unlike traditional solvent-based coatings, Waterborne Acrylic Resin emits very low levels of volatile organic compounds (VOCs), making it a more sustainable and environmentally-friendly option.The introduction of Waterborne Acrylic Resin by elite coating company is a testament to the company's commitment to innovation and sustainability. With a strong focus on research and development, the company continuously strives to develop cutting-edge coating solutions that meet the ever-evolving needs of the industry while reducing its environmental impact. The launch of Waterborne Acrylic Resin is a step towards achieving this goal.The new product is expected to have a significant impact on the coatings industry. Its superior performance and eco-friendly features make it a highly desirable option for manufacturers and consumers alike. In addition to its sustainability benefits, Waterborne Acrylic Resin also offers cost savings and operational efficiencies, making it a compelling choice for businesses looking to improve their bottom line while reducing their environmental footprint.One of the key advantages of Waterborne Acrylic Resin is its excellent adhesion properties. It forms a strong bond with various substrates, including metal, plastic, and wood, ensuring long-lasting and durable coatings. This makes it well-suited for a wide range of applications, from automotive and industrial coatings to architectural and decorative finishes.Furthermore, Waterborne Acrylic Resin offers outstanding weather resistance, making it suitable for outdoor applications. It provides protection against harsh environmental conditions, such as UV exposure, moisture, and temperature fluctuations, ensuring that the coated surfaces maintain their appearance and performance over time.The eco-friendly nature of Waterborne Acrylic Resin is another major selling point. By significantly reducing VOC emissions, the new product helps companies comply with increasingly stringent environmental regulations while contributing to a healthier and more sustainable planet. This makes it a great choice for businesses looking to enhance their environmental credentials and demonstrate their commitment to sustainability.Elite coating company has invested significant resources into the development and production of Waterborne Acrylic Resin. The company's state-of-the-art manufacturing facilities and rigorous quality control processes ensure that the product meets the highest standards of performance and reliability. Customers can have confidence in the consistency and performance of Waterborne Acrylic Resin, knowing that it has been developed and tested by a leading industry expert.As the coatings industry continues to evolve, the demand for high-performance, eco-friendly solutions will only increase. The introduction of Waterborne Acrylic Resin by elite coating company is a timely response to this growing need. With its exceptional performance, sustainability benefits, and cost savings potential, the new product is set to make a significant impact on the market.In conclusion, the introduction of Waterborne Acrylic Resin by elite coating company represents a major milestone in the coatings industry. The new product is expected to set a new standard for performance, sustainability, and cost-effectiveness, making it a top choice for manufacturers and consumers alike. With its superior adhesion, weather resistance, and eco-friendly features, Waterborne Acrylic Resin is set to revolutionize the way coatings are used across various industries. Elite coating company's dedication to innovation and sustainability has culminated in the development of this groundbreaking product, which is poised to shape the future of the coatings industry for years to come.

Flexible 3D Domed Decals for Rims, Knobs and Remotes at CrossfireMarket

In the world of automotive customization, finding the perfect vendor for parts is crucial. Whether you're looking to enhance the appearance of your car or improve its performance, having top-quality parts is a must. One such vendor that has caught our attention recently is CrossfireMarket BestStickers.Net Jelgava, who offer a range of domed emblems for rims, knob and remote.One of their most impressive offerings is the 3D domed flexible decal. This unique decal is domed with 3D Gel (Polyurethane Resin) to create a stunning 3D effect that is sure to turn heads. The flexibility of the decal also makes it easy to apply to curved surfaces, such as car rims, without any wrinkling or lifting.The Polyurethane Resin plays a crucial role in the durability and longevity of the decal. It is a 2 part system that combines a resin and a hardener to create a strong, flexible material that can withstand the harsh elements, including UV rays and extreme temperatures. The result is a decal that will maintain its shape, color, and shine for years to come.One of the best things about these decals is their versatility. Not only can they be used on car rims, but they can also be applied to other parts of your vehicle, such as the steering wheel, gear knob, or even the remote key fob. This allows you to customize your car to your own unique style, making it stand out from the crowd.But it's not just the quality of the product that sets CrossfireMarket BestStickers.Net Jelgava apart from the competition. They also offer exceptional customer service, ensuring that their clients are completely satisfied with their purchase. They take great pride in their work and make every effort to meet their clients' needs and expectations.In conclusion, if you're looking for top-quality automotive decals, look no further than CrossfireMarket BestStickers.Net Jelgava. Their 3D domed flexible decals, made with 2 part Polyurethane Resin, will not disappoint. Their attention to detail and commitment to customer satisfaction sets them apart from the rest. So go ahead and give your car the upgrade it deserves with a set of these stunning decals.

New Polyurethane Car Technology Revolutionizes Automotive Industry

The demand for sustainable and environmentally friendly transportation options has been on the rise in recent years. As more and more consumers become conscious of the impact of their choices on the planet, the automotive industry has been forced to evolve and adapt to the changing needs of the market. In response, {Company Name} has announced the development of a new car model that is made with polyurethane, a material known for its durability and eco-friendly properties.{Company Name} is a global leader in the automotive industry, with a strong commitment to innovation and sustainability. The company has been at the forefront of developing new technologies and materials to create vehicles that are not only high-performing but also environmentally responsible. With a strong focus on research and development, {Company Name} has continuously invested in sustainable solutions to meet the growing demands for greener transportation options.The new car model, which has been in development for several years, is a result of intensive research and collaboration with leading experts in the field of materials science. The use of polyurethane in the manufacturing of the vehicle has several benefits, including its light weight, high strength, and low environmental impact. Polyurethane is a versatile material that can be molded into various shapes and forms, making it an ideal choice for car manufacturing.In addition to its physical properties, polyurethane is also a sustainable choice for car production. Unlike traditional materials such as steel and aluminum, polyurethane can be produced with lower energy consumption and emissions, making it a more eco-friendly option. This aligns with {Company Name}'s commitment to reducing its carbon footprint and promoting sustainability throughout its operations.The new car model is expected to set a new benchmark in the automotive industry, showcasing the potential for integrating advanced materials into vehicle production. The use of polyurethane not only enhances the overall performance of the car but also contributes to a more sustainable future for transportation. {Company Name} is proud to be leading the way in this aspect, demonstrating its dedication to innovation and environmental responsibility.Moreover, {Company Name} has also focused on creating a car that is not only environmentally friendly but also meets the highest standards of safety and comfort. The new model features state-of-the-art technology and design, providing a smooth and efficient driving experience for consumers. With a focus on sustainable mobility, the car is designed to minimize its impact on the environment while delivering a high level of performance and reliability.The use of polyurethane in the new car model is just one example of {Company Name}'s ongoing commitment to sustainable development. The company has set ambitious sustainability targets and has implemented various initiatives to reduce its environmental footprint. From improving energy efficiency in its manufacturing facilities to promoting the use of renewable materials, {Company Name} is dedicated to being a leader in sustainable automotive production.In addition to its environmental efforts, {Company Name} has also been a pioneer in promoting electric and hybrid vehicles. The company has invested heavily in the development of electric propulsion technologies and has made significant strides in creating more efficient and affordable electric cars. By combining its expertise in sustainable materials with its advancements in electric and hybrid technology, {Company Name} is poised to revolutionize the automotive industry and set new standards for environmentally friendly transportation.The introduction of the new car model made with polyurethane represents a significant step forward in {Company Name}'s journey towards a more sustainable future. The company's dedication to innovation and sustainability has positioned it as a leader in the automotive industry, and the new car model is a testament to its ongoing commitment to creating a greener, more sustainable world. As the demand for eco-friendly transportation options continues to grow, {Company Name} is well-equipped to meet the needs of consumers while making a positive impact on the planet.

Exploring the Benefits and Uses of Water-Based Polyurethane Resin

Title: New Water-Based Polyurethane Resin Revolutionizes Coatings IndustryIntroduction:In recent years, there has been an increasing demand for eco-friendly and high-performance coatings with minimal volatile organic compounds (VOCs) for various applications ranging from construction to automotive. Addressing these needs, a leading manufacturer in the chemicals industry has introduced an innovative water-based polyurethane resin, transforming the landscape of the coatings industry. This resin offers exceptional versatility, reduced environmental impact, and top-tier performance, positioning it to become a game-changer in the market.Company Overview:Founded in [year], [Company Name] has established itself as a pioneer in chemical manufacturing, with a strong focus on research and development. The company leverages its state-of-the-art facilities and expertise to develop cutting-edge solutions to meet industry-specific demands. With a commitment to sustainable practices and environmental conservation, [Company Name] operates under the highest quality and safety standards while prioritizing customer satisfaction.Innovation in Water-Based Polyurethane Resin:[Company Name] has unveiled its latest breakthrough, a water-based polyurethane resin that promises to revolutionize the coatings industry. Combining the benefits of traditional solvent-based polyurethane with water-based technology, this resin marks a significant milestone in delivering exceptional performance while minimizing environmental impact.1. Enhanced Performance:The water-based polyurethane resin offers superior mechanical properties, including excellent adhesion, hardness, and impact resistance, rivaling those of solvent-based counterparts. Its ability to maintain flexibility and durability even in harsh conditions makes it ideal for a wide range of applications, such as automotive, furniture, and industrial coatings. Furthermore, this resin exhibits remarkable resistance to abrasion, UV rays, chemicals, and weathering, ensuring long-lasting protection and extending the lifespan of coated surfaces.2. Eco-Friendly Solution:Compared to solvent-based resins, the water-based polyurethane resin significantly reduces VOC emissions. VOCs are known to contribute to air pollution and have adverse effects on human health and the environment. By minimizing VOC content, this resin aligns with global initiatives to mitigate environmental impact without compromising on performance. Additionally, the resin's water-based formulation allows for easy cleanup and eliminates the need for hazardous chemicals during application, making it safer for both users and the environment.3. Versatile Applications:The flexibility of the water-based polyurethane resin opens doors to a myriad of coating applications. From interior and exterior architectural coatings to coatings for wood, metal, plastic, and concrete surfaces, this resin showcases its adaptability across numerous industries. Its compatibility with various pigments and additives allows customized solutions to cater to specific performance requirements and aesthetic preferences. Moreover, the resin can be easily applied using conventional coating techniques, offering a seamless transition for manufacturers and applicators.Future Prospects:[Company Name]'s water-based polyurethane resin offers a glimpse into the future of the coatings industry. With an increasing emphasis on sustainable practices and stringent environmental regulations, this innovative solution is positioned to replace conventional solvent-based resins and dominate the market. The technologically advanced resin not only meets current demands but also paves the way for further advancements in eco-friendly coatings that prioritize performance, longevity, and environmental responsibility.Conclusion:The introduction of water-based polyurethane resin by [Company Name] brings a new era of sustainable, high-performance coatings. By combining exceptional mechanical properties with reduced environmental impact, this resin offers a reliable, versatile, and eco-friendly solution for various industries. With its ability to address the industry's need for reduced VOC emissions while maintaining durability, the water-based polyurethane resin has the potential to shape a greener future for the coatings industry and beyond.

Durable and Versatile Transparent Polyurethane Resin: A Closer Look

[Company Introduction] is a leading manufacturer and supplier of high-quality chemicals and materials for various industries. The company is committed to providing innovative solutions that meet the unique needs of their customers. With a focus on research and development, [Company Name] has been at the forefront of developing advanced materials that are used in a wide range of applications.One of their latest innovations is the development of Transparent Polyurethane Resin, which is a versatile and high-performance material that offers numerous benefits across different industries. This new product has been received with great excitement and has garnered a lot of attention from manufacturers, engineers, and designers.[Company Name] has a dedicated team of researchers and scientists who have worked tirelessly to develop this innovative polyurethane resin. Their expertise and knowledge in the field of materials science have enabled them to create a product that meets the highest standards of quality and performance. With a focus on sustainability and environmental responsibility, [Company Name] has also ensured that the manufacturing process for this resin is eco-friendly.The Transparent Polyurethane Resin is a clear, durable, and versatile material that offers a wide range of benefits. It has excellent adhesion properties, making it suitable for use in coatings, adhesives, and sealants. The high optical clarity of the resin also makes it ideal for use in optical lenses, electronic displays, and other transparent applications. Additionally, the resin has outstanding flexibility, impact resistance, and chemical resistance, making it a preferred choice for demanding applications.One of the key advantages of Transparent Polyurethane Resin is its ability to enhance the aesthetics and performance of various products. Its excellent weathering and UV resistance properties make it suitable for outdoor applications, such as automotive coatings and architectural glazing. The material also offers excellent mechanical properties, making it suitable for use in structural components and consumer goods.Moreover, the resin has a wide processing window and can be customized to meet specific requirements. This versatility makes it suitable for use in a wide range of manufacturing processes, including casting, molding, and 3D printing. Its compatibility with different additives and fillers further expands its potential applications across various industries.[Company Name] is committed to providing comprehensive technical support and expertise to their customers to ensure the successful implementation of Transparent Polyurethane Resin in their products. The company's dedicated team of experts is available to assist with product selection, formulation development, and process optimization. This level of support and collaboration sets [Company Name] apart as a trusted partner for manufacturers and designers seeking innovative material solutions.With the introduction of Transparent Polyurethane Resin, [Company Name] has once again demonstrated its commitment to innovation and excellence. This new product represents a significant advancement in the field of materials science and has the potential to transform various industries. As the demand for high-performance materials continues to grow, [Company Name] is well-positioned to meet the needs of their customers with cutting-edge solutions like Transparent Polyurethane Resin.

Polyurethane Laminating Adhesive Market Poised for Exponential Growth by 2022-2028, Says Report

Market, Global Market Size, Analysis, Growth, Trends, Forecasting, Applications, Industry Overview, Market Segmentation, Competitive Landscape, Regional Analysis, Opportunities, Challenges, and Future Outlook.Polyurethane Laminating Adhesive Market: Analysing the Global Market Size, Growth and OpportunitiesAs per the recent report published by The Galleon, the Polyurethane Laminating Adhesive market is expected to observe exponential growth between the years 2022 and 2028. The report provides a detailed analysis of the global market size, growth, trends, and opportunities in the Polyurethane Laminating Adhesive industry, including key drivers, challenges, and future outlook.Overview of the Polyurethane Laminating Adhesive MarketPolyurethane Laminating Adhesives (PULAs) are used in the production of flexible laminates and coatings for various industries, including textiles, automotive, construction, and packaging. These adhesives offer a high level of adhesion strength, durability, and flexibility, making them an ideal choice for bonding different materials, such as metals, plastics, and textiles.The global Polyurethane Laminating Adhesive market is segmented based on type, application, and region. The type segment includes solvent-based, water-based, and hot melt PULAs, while the application segment includes textiles, automotive, construction, packaging, and others.Market SegmentationBased on type, the water-based PULAs segment is expected to witness the highest growth rate over the forecast period, owing to its eco-friendly nature and low volatile organic compound (VOC) emissions. Furthermore, the packaging application segment is projected to gain maximum market share due to the rise in demand for flexible packaging solutions across the globe.Regional AnalysisGeographically, the Polyurethane Laminating Adhesive market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East and Africa. The Asia-Pacific region is expected to dominate the market share, owing to the high demand for PULAs in the rapidly growing end-use industries, such as textiles and packaging. Moreover, the increasing urbanization and rising per capita income levels in emerging economies, such as China and India, are expected to boost the demand for PULAs in the region.Industry Overview and TrendsThe Polyurethane Laminating Adhesive market is highly competitive and fragmented, with the presence of several market players, including market leaders, such as 3M, Avery Dennison Corporation, and Henkel AG & Co. KGaA, and regional players, such as Rakoll GmbH, Bond Tech Industries, and Bondex, Inc.Moreover, the market players are focusing on various strategies, such as product innovation, mergers and acquisitions, partnerships, and collaborations, to gain a competitive edge in the market. For instance, in 2020, H.B. Fuller Company completed the acquisition of Adecol Ind. Quimica, a Brazilian-based manufacturer of adhesive technologies, including PULAs, to expand its product portfolio in the Latin American market.Opportunities and ChallengesThe Polyurethane Laminating Adhesive market presents several opportunities, such as increasing demand for sustainable and eco-friendly adhesives, rising investments in research and development activities, and growing adoption of PULAs in the automotive and construction industries.However, the market also faces several challenges, such as fluctuating raw material prices, stringent environmental regulations, and increasing competition from alternative adhesive technologies.Future OutlookIn conclusion, the Polyurethane Laminating Adhesive market is expected to witness significant growth over the forecast period, owing to the increasing demand for PULAs in various end-use industries, such as packaging, textiles, automotive, and construction. Furthermore, the market players are expected to focus on various strategies, such as product innovation, partnerships, and mergers and acquisitions, to gain a competitive edge in the market.

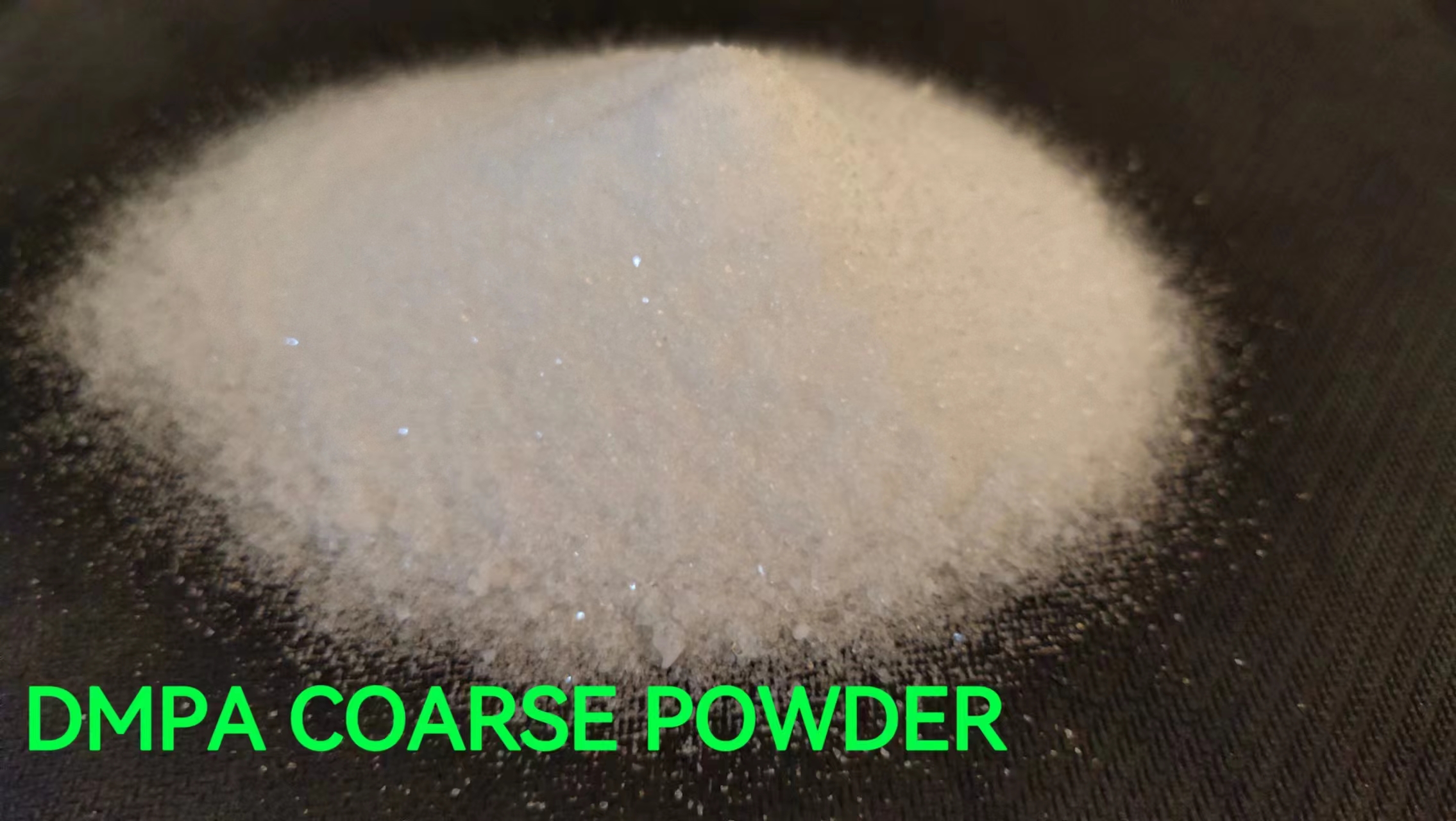

Innovative 2-Dimethylolpropionic Acid: A Breakthrough in Chemical Technology

2-Dimethylolpropionic Acid, a versatile chemical compound used in various industries, has gained significant attention in recent years due to its wide range of applications and benefits. One of the leading manufacturers of this compound, {} (remove brand name), has been at the forefront of its production and distribution, making significant contributions to the industry.{} (remove brand name) has been a key player in the production of 2-Dimethylolpropionic Acid for several years, consistently delivering high-quality products to meet the diverse needs of its customers. The company's commitment to excellence and innovation has positioned it as a trusted supplier in the global market, catering to a wide range of industries such as adhesives, coatings, textiles, and more.2-Dimethylolpropionic Acid, also known as DMPA, is a multifunctional chemical compound with a unique structure that offers various advantages in different applications. It is widely used as a building block in the production of waterborne polyurethane dispersions, which are essential in the manufacturing of environmentally friendly coatings and adhesives. Additionally, DMPA is used as a crosslinking agent in the production of polyester resins, contributing to the improvement of the overall performance and durability of the final products.The versatility of 2-Dimethylolpropionic Acid extends to the textile industry, where it is utilized as a finishing agent to enhance the performance of fabrics. Its hydrophilic nature and reactive functionality make it an ideal additive for improving the dyeability and moisture management properties of textiles, resulting in high-quality, functional fabrics for various applications.Furthermore, DMPA plays a crucial role in the production of high-performance adhesives, particularly in the construction and automotive industries. Its ability to improve adhesion, flexibility, and water resistance makes it a valuable component in the formulation of adhesives for bonding a wide range of substrates, including metals, plastics, and composites.In addition to its functional benefits, 2-Dimethylolpropionic Acid is also valued for its eco-friendly characteristics. As a water-based compound, it aligns with the growing demand for sustainable and environmentally responsible solutions in various industries. This has further propelled its demand and adoption in the global market, with an increasing number of manufacturers and end-users recognizing the importance of incorporating green and sustainable materials into their products and processes.{} (remove brand name) has been instrumental in promoting the sustainable use of 2-Dimethylolpropionic Acid, advocating for its benefits and raising awareness about its potential applications across different industries. The company's dedication to research and development has led to the continuous improvement of its DMPA products, meeting the evolving needs and standards of the market while also ensuring environmental sustainability.As a leading supplier of 2-Dimethylolpropionic Acid, {} (remove brand name) has established itself as a reliable partner for businesses seeking high-quality and sustainable chemical solutions. With a global presence and a strong focus on customer satisfaction, the company has consistently delivered exceptional products and services, earning the trust and loyalty of its clients around the world.In conclusion, the increasing demand for sustainable and high-performance chemical compounds has propelled the prominence of 2-Dimethylolpropionic Acid in numerous industries. With its versatile applications and eco-friendly characteristics, DMPA has become a sought-after ingredient in the formulation of coatings, adhesives, textiles, and more. {} (remove brand name) has played a pivotal role in driving the adoption and advancement of DMPA, showcasing its dedication to innovation, sustainability, and customer satisfaction. As the market continues to evolve, 2-Dimethylolpropionic Acid is poised to remain a key player in the realm of modern chemical solutions, contributing to the development of innovative and sustainable products across various sectors.

Revolutionary Water-Based Binder Enhances Composite Metals Industry with Fast Drying and Longer Shelf Life

The world of composite metals industry is constantly evolving, and one of the latest and exciting innovations in the sector is the introduction of water-based binders. These binders, which are formulated using water as their base, are becoming increasingly popular among manufacturers, businesses, and individuals working with metals.Water-based binders have revolutionized the way in which metal coatings are applied. They provide a safer and more practical alternative to solvent-based coatings that traditional contain harmful chemicals. These binders have all the benefits of solvent-based coatings, but without the dangerous and unpleasant fumes. They are non-toxic and environmentally friendly options for a wide range of applications.One of the most notable advantages of a water-based binder is the exclusive pleasant odor it emits. Contrary to the pungent smell of solvents, water-based binders have a subtle and less intense aroma, which makes it an ideal solution for enclosed spaces or rooms with poor ventilation.Another significant feature of water-based binders is its fast-drying property. This capability significantly reduces labor costs by speeding up the entire process. Besides, fast drying translates to time efficiency, allowing faster productivity and prompt delivery of service to clients.The wash-up solution is also another practical benefit of water-based binders. With traditional metal coatings, cleaning up is a tedious process, but water-based binders, simply require washing with water and soap to remove from surfaces, equipment, and tools.Longer shelf life is another crucial benefit of water-based binders. These products have enhanced stability and can be stored for extended periods without fear of degradation or coagulation. This attribute makes water-based binders an excellent fit for businesses that require high volume production but do not need to use up the product immediately.Furthermore, water-based binders are compatible with a broad range of materials. Whether it's aluminum, mild steel, copper, or other light alloys, water-based binders provide superior adhesion and bonding with minimal pre-treatment or heating requirements. This exceptional feature is instrumental in meeting specific application requirements and for innovative experimental testing of various metals.In conclusion, water-based binders have changed the world of composite metals industry. Its exclusive, pleasant odor, fast-drying, environmentally friendly and more natural wash-up solution, longer shelf life are its obvious benefits. Applications of these binders go beyond the traditional metal coating industry into broader areas such as automotive industries, anti-corrosion coatings, architecture, and aerospace. Water-based binders will continue to revolutionize the composite metal industry, offering sustainable, user-friendly, and practical solutions for various industrial and home applications.

New Water-Based Dispersion Technology Shows Promise For Sustainable Production

Title: Industry-Leading Water Based Dispersion Revolutionizes Coating SolutionsIntroduction:With a commitment to innovation and sustainable solutions, {Company Name} has introduced a cutting-edge Water Based Dispersion that is set to revolutionize the coating industry. Offering unparalleled performance and eco-friendly attributes, this breakthrough product is poised to change the landscape of coatings across various sectors. Through years of research and development, {Company Name} has successfully created a game-changing solution catering to the ever-evolving needs of modern industries.Unveiling a Sustainable Coating Solution:{Company Name}'s Water Based Dispersion is an advanced and environmentally friendly coating solution derived from state-of-the-art technology. This breakthrough product represents a significant achievement in the coatings industry, combining exceptional performance with a focus on reducing environmental impact.Sustainable Formulation:The water-based nature of this dispersion makes it free from volatile organic compounds (VOCs), which are harmful substances that contribute to air pollution and have detrimental effects on human health. By eliminating VOCs, {Company Name} has developed a sustainable coating option that meets stringent regulatory standards without compromising performance.Superior Performance:{Company Name}'s Water Based Dispersion offers superior performance across various applications. It provides excellent viscosity control, allowing for ease of application. This dispersion also ensures exceptional adhesion properties, resulting in durable coatings that maintain their integrity even in challenging environments. Additionally, the product exhibits excellent resistance to humidity, UV radiation, and chemicals, making it suitable for a wide range of applications.Versatile Applications:This innovative dispersion has found uses in numerous industries, including automotive, construction, consumer goods, and industrial settings. Its exceptional chemical resistance, durability, and flexibility make it a go-to choice for coating metal products, exterior surfaces, and consumer goods. Whether used for protective coatings on automobiles or enhancing the longevity of furniture, the versatility of this dispersion caters to a broad range of applications.Enhanced Sustainability Profile:{Company Name}'s Water Based Dispersion significantly reduces the environmental impact associated with traditional coating technologies. By eliminating VOCs, this dispersion minimizes harmful emissions, making it eco-friendly and promoting cleaner air and healthier environments. It also reduces the amount of hazardous waste generated during application, further contributing to a sustainable future.Investment in Research and Development:Behind every breakthrough product is a dedication to continuous research and development. {Company Name} invested substantial resources to develop this Water Based Dispersion, prioritizing sustainability and meeting the evolving demands of various industries. The company's commitment to innovation and its emphasis on creating sustainable coating solutions drive its ongoing quest for excellence.Collaboration with Industry Stakeholders:{Company Name} actively collaborates with industry stakeholders, including manufacturers, regulatory bodies, and customers, to ensure its products adhere to industry standards and exceed customer expectations. Through partnerships and open communication, {Company Name} continuously gathers feedback and insights to refine its products further.Conclusion:{Company Name}'s Water Based Dispersion has emerged as a game-changer in the coatings industry, offering exceptional performance while prioritizing sustainability. By eliminating VOCs and incorporating advanced technology, this innovative product revolutionizes coating solutions. {Company Name}'s commitment to research, collaboration, and environmental stewardship positions them as an industry leader in providing eco-friendly and high-performance coating options. With the introduction of this revolutionary Water-Based Dispersion, {Company Name} contributes to a more sustainable future while meeting the needs of a rapidly evolving market.